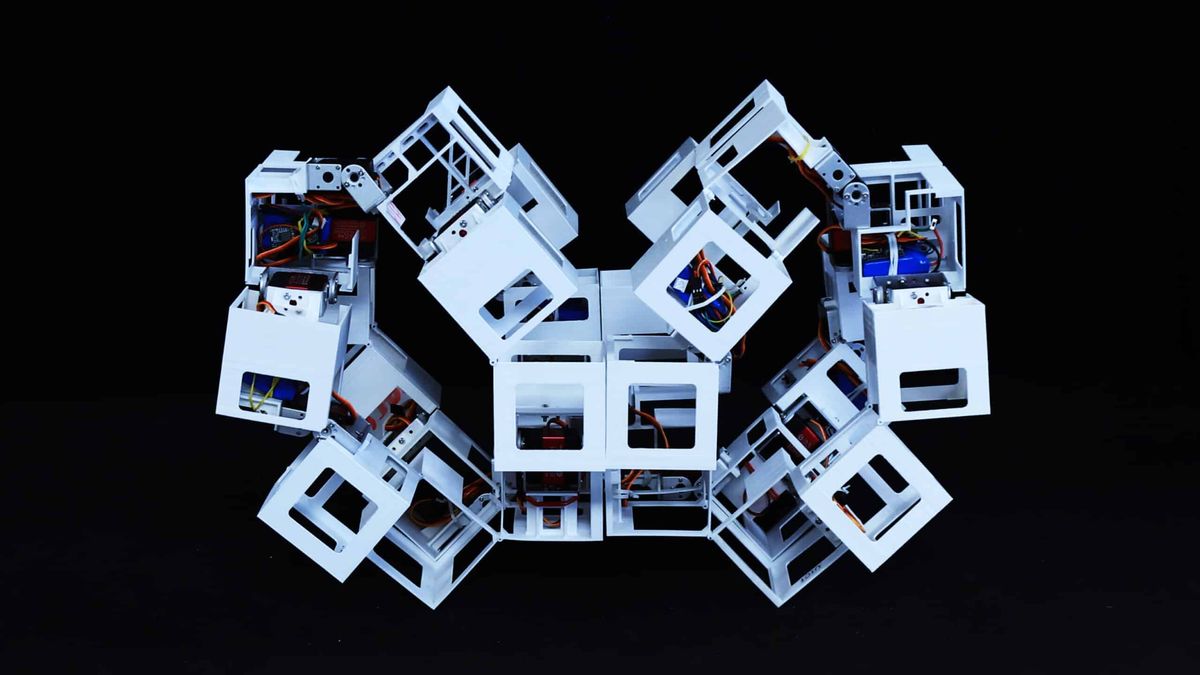

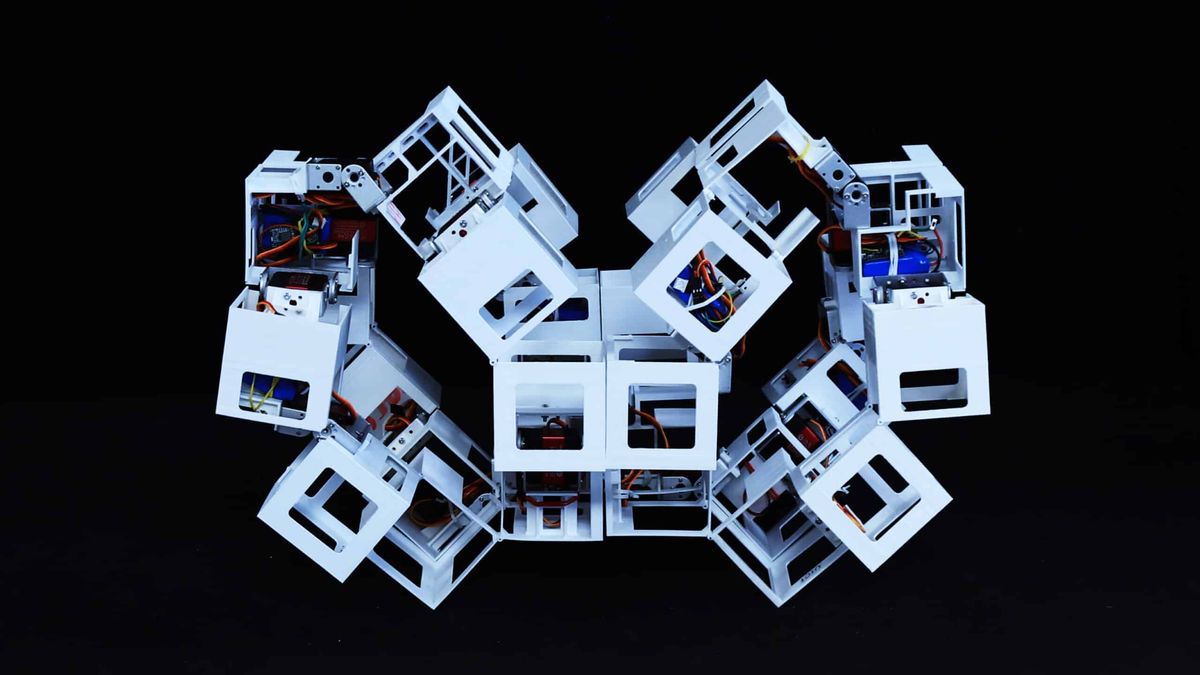

A newly designed “transformer” robot with the ability to change shape could one day be used to build habitats in space.

Engineers from North Carolina State University (NC State) have created a plastic cubed structure that can transform into more than 1,000 configurations using only three active motors. In theory, their design — which was largely inspired by the paper-folding art of origami — offers a more efficient way to send assembly structures into space, where the robot could then “transform” to serve various purposes, including carrying a load, according to an NC State statement.

“We think these can be used as deployable, configurable space robots and habitats,” Antonio Di Lallo, co-first author of the study and an NC State postdoctoral researcher, said in the statement. “It’s modular, so you can send it to space flat and assemble it as a shelter or as a habitat, and then disassemble it.”

The team’s transformer bots consist of 36 3D-printed hollow, plastic cubes assembled with rotating hinges. Some of the hinges are fixed with metal pins, while others are activated wirelessly with a motor. The researchers were able to transform the robotic structures into various shapes, ranging from tunnels and bridges to multi-story architectures.

“The question we’re asking is how to achieve a number of versatile shapes with the fewest number of actuators powering the shapeshifting,” Jie Yin, co-author of the study and associate professor of mechanical and aerospace engineering at NC State, said in the same statement. “Here we use a hierarchical concept observed in nature — like layered muscle fibers — but with plastic cubes to create a transforming robot.”

Related: Could these big expandable habitats help humanity settle the moon and Mars?

RELATED STORIES:

In the process of changing shape, the transformer bots are able to move forward, backward and sideways. The bots can transform relatively quickly from flat, or fully open, to a box-like larger cube, or fully closed structure. They can also carry a load about three times their own weight and travel up an inclined surface, according to the statement.

“We want to make a more robust structure that can bear larger loads,” Yanbin Li, co-author of the study and an NC State postdoctoral researcher, said in the statement. “If we want a car shape, for example, how do we design the first structure that can transform into a car shape? We also want to test our structures with real-world applications like space robots.”

Their findings were published July 26 in the journal Nature Communications.